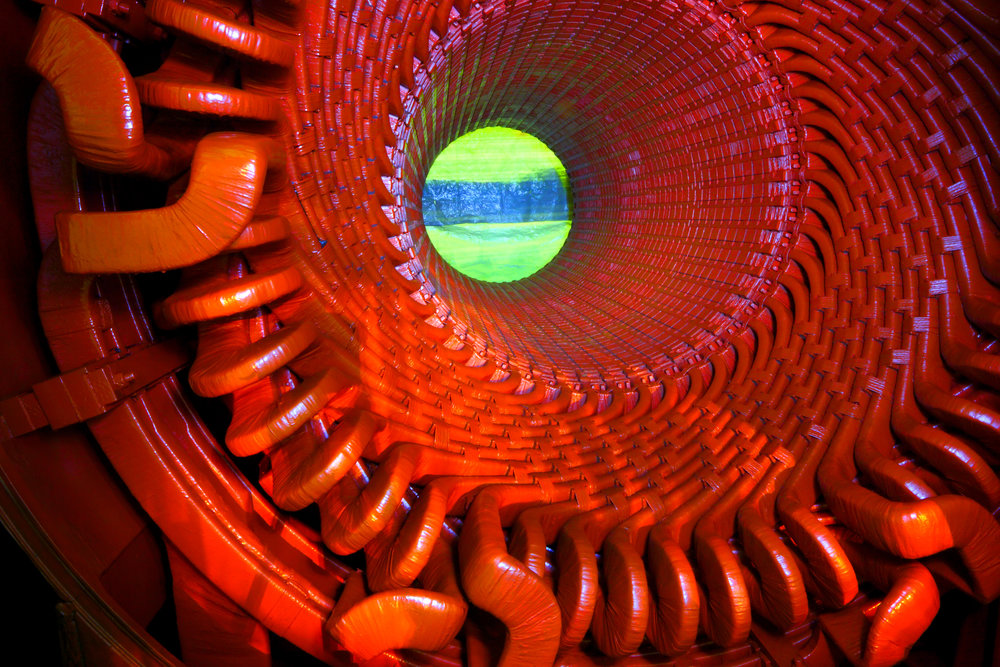

Powertech’s Generation Services group provides qualification testing, insulation system evaluation, and failure analysis of stator bars/coils for generators and motors.

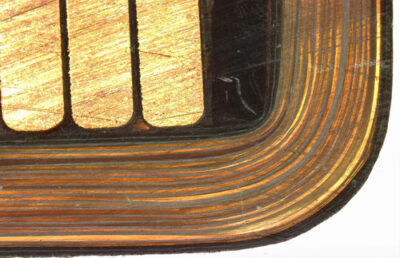

A reliable stator winding insulation system is essential to ensure that generators and motors can provide long-term service under various operating conditions. Stator windings are subjected to electrical, mechanical, thermal, and environmental stresses, causing gradual degradation of the insulation throughout its service life. Most premature failures of the machine can be avoided if proper manufacturing processes and qualification tests of the insulation system are followed. Accelerated aging tests such as thermal cycling and voltage endurance are designed to simulate lifetime performance of the insulation system.

New or rewound stator bars/coils must be manufactured to high levels of quality and meet the performance requirements of the rotating machines. Qualification tests can be conducted on sample bars/coils to identify possible manufacturing defects and reduce in-service insulation failure, which can lead to long repair times or costly stator rewind. Our Stator Laboratory offers complete test packages for testing stator bars/coils in accordance with industry standards and client specifications.

Powertech is experienced in conducting qualification and acceptance tests for stator bars/coils from a wide variety of OEMs and utilities. Our Stator Winding Insulation Laboratory provides independent, third-party evaluation of the insulation quality and performance of stator bars/coils.

Qualification tests and services include:

- Voltage endurance (IEEE 1043/1553)

- Thermal cycling (IEEE 1310)

- Partial discharge (IEEE 1434)

- Dissipation factor and tip-up (IEEE 286)

- Turn-to-turn surge/impulse (IEEE 522)

- Blackout and corona scope (IEEE 1799)

- Insulation resistance/polarization index (IEEE 43)

- DC ramp and step test (IEEE 95)

- AC/DC withstand and breakdown test

Analysis Services:

- Dissection and microscopic examination

- Insulation material analysis (glass transition temperature and organic binder)

- Failure analysis

- Factory acceptance testing oversight

- Technical specification review

Generation Services

The Powertech Generation Services group is focused on large power generators, providing condition assessment and specialized diagnostic tests, performance and acceptance testing of stator bars and coils for OEMs and asset owners, and testing and modelling of generator performance for NERC and WECC compliance.

For more information contact: