Powertech Offers Reliable, Cost-Efficient System

Canadian utilities have been given the challenge to comply with federal Polychlorinated Biphenyl (PCBs) regulations, made under the authority of the Canadian Environmental Protection Act, to stop using any electrical equipment that contains more than 50 parts per million (ppm) (mg/kg), by 2025. PCBs were widely used as insulating fluids in electric equipment until the late 1970s, when their use was prohibited due to environmental and health concerns. Although production of PCBs and their use in new equipment have stopped, they remain in many legacy pieces of electrical equipment.

POLE-TOP AND PADMOUNT TRANSFORMERS AND PCBs

Some of the most difficult electrical equipment to comply with these regulations are pole-top and padmount (underground distribution) transformers.

Electric utilities have typically employed two strategies to meet compliance with these widely dispersed devices. One strategy—wholesale replacement of specified-age transformers—is expensive and can replace transformers that could have decades of life remaining. The other strategy—oil sampling—requires drilling, and subsequently sealing a hole in transformers. This strategy has been tainted by past industry practices that can lead to corrosion and premature failure of the transformer.

POWERTECH’S RELIABLE, COST-EFFICIENT SAMPLING SYSTEM

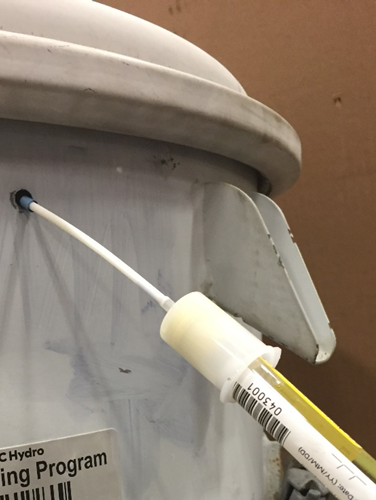

Powertech’s integrated sampling system consists of specialized live line tools, sampling siphon and vial, sealing rivet and paint, and field transport packaging. The system, which has been field-tested by BC Hydro and other Canadian utilities, provides a means of efficiently and safely sampling as well as reliably sealing transformers. In addition, the sampling system can be used on energized transformers, which avoids customer electricity interruptions.

Because the system is designed to be used by qualified power-line technicians (PLTs), utilities can provide it to their own PLT resources or local contractor PLT crews. By using a trusted system, utilities can obtain competitive labour bids for sampling.

TOOL KITS

- Tool Kit for De-Energized Work

- Tool Kit for Energized Work

- Tool Kit for Energized/De-Energized Work (Combo Kit)

SAMPLE/SEAL KITS

- Sample/Seal Kit

- Sample/Seal Kit with included PCB Analysis and shipping

TRAINING

- Available at Powertech Labs or customer site

- Remote, web-based training available

POWERTECH LABORATORY TESTING

As part of the sampling system, Powertech’s Applied Chemistry Lab—which has more than 40 years’ experience in electrical equipment testing—can also perform transformer oil PCB concentration testing to ISO 9001, ISO 17025, and CALA standards.

POWERTECH’S OIL SAMPLING SYSTEM

- Live line tools

- Sampling siphon and vial

- Sealing rivet and paint

- Field transport packaging

FOR MORE INFORMATION: