Powertech’s materials testing laboratory features extensive facilities providing a wide variety of services. Performing services such as failure analysis, material evaluation and development, and mechanical testing, the materials testing lab also functions as a support laboratory for various other services offered by Powertech. Our competent technical and professional staff offers experience with metals, polymers, ceramics, and composites to aid in testing and analysis for industry, government, litigation, insurance, and research purposes.

Mechanical Properties

- ensile and compression (up to 400,000 lbs)

- Impact energy

- Fracture toughness

- Fatigue crack growth rate

- Shear

- Bend (cantilever, three point, etc.)

- Spring constant testing

- Hardness and microhardness

Materials Testing & Analysis

- Condition assessment

- Fitness for service

- Adherence to design specification

- Microstructure analysis

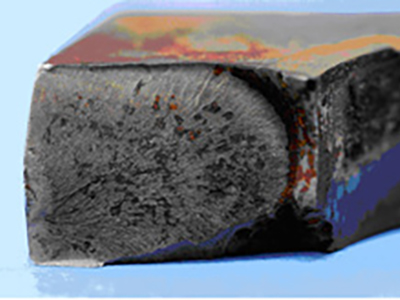

Failure Analysis

- Fatigue

- Corrosion

- Creep

- Cavitation erosion

- Overload (torsion, tension, bending, etc.)

- Defects

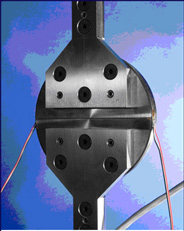

Other Capabilities Include:

- Welding engineering

- Sample preparation

- Scanning electron microscopy

- Energy dispersive spectroscopy

- Optical microscopy

- Friction testing

- Instrument calibration

- Reverse engineering