Specialized leading-edge testing of fill materials for embankment dams.

Internal erosion occurs when the hydraulic forces exerted by seepage flow through a dam are sufficient to overcome the resistant forces and cause particle detachment. Internal erosion represents a significant risk to embankment dams and accounts for nearly half of all dam safety incidents. Due to challenges with assessing internal erosion in-situ and the lack of availability of numerical models, non-standardized laboratory tests and empirical methods are primarily relied on.

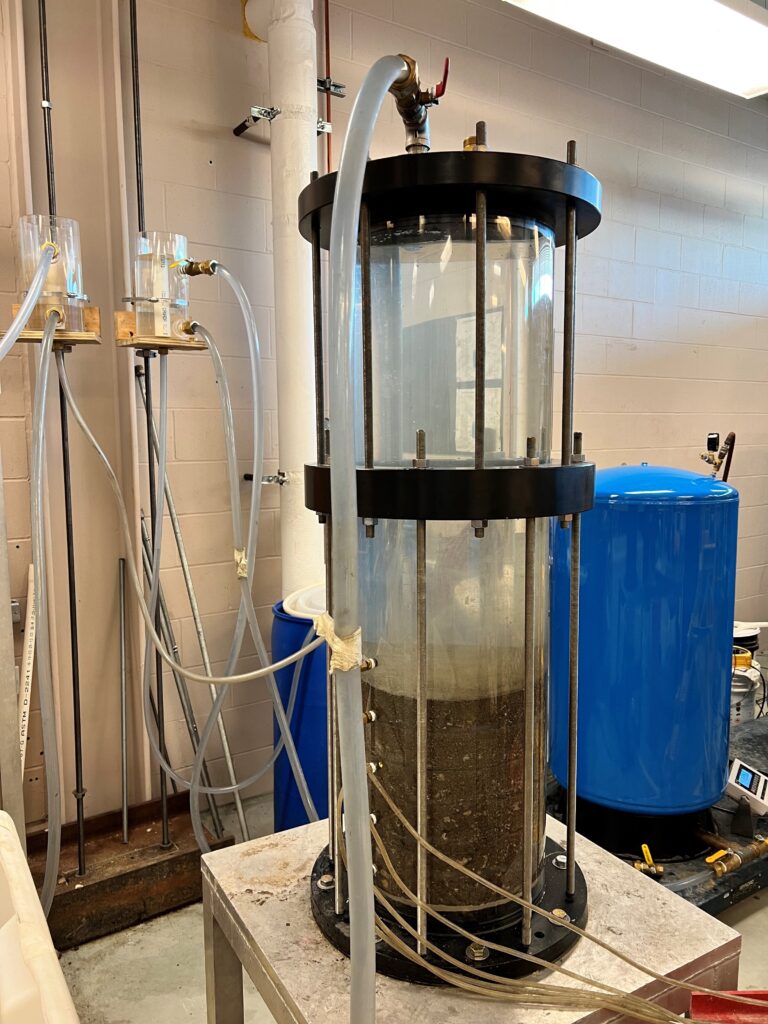

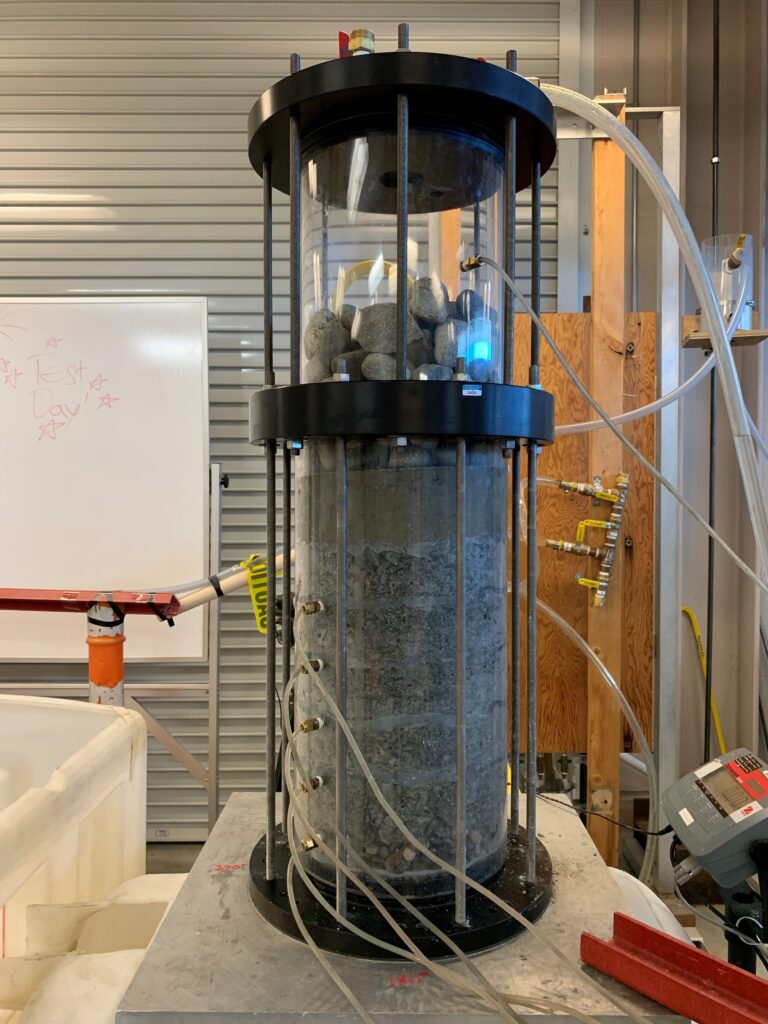

Powertech has developed state-of-the-art test equipment to assess filter performance of embankment dams using:

- a 100-mm diameter permeameter cell for fine-grained soils, or

- a 300-mm diameter permeameter cell with maximum particle size up to 37.5 mm, or

- a 500-mm diameter permeameter cell with maximum particle size up to 75 mm, or

- a 1000-mm diameter permeameter cell in development, with a maximum particle size up to 125 mm

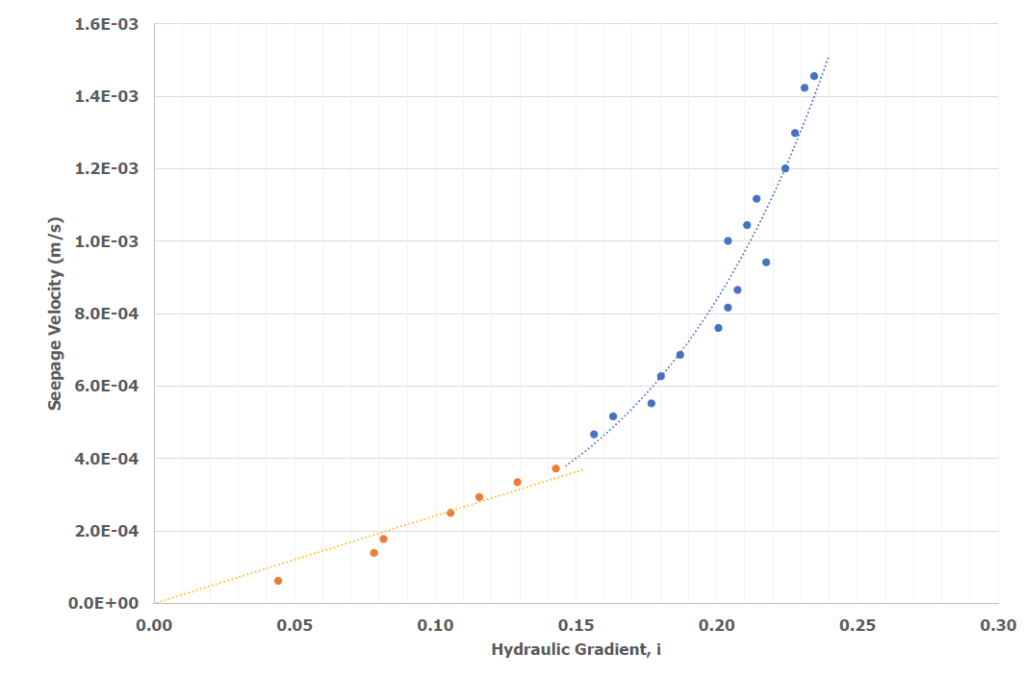

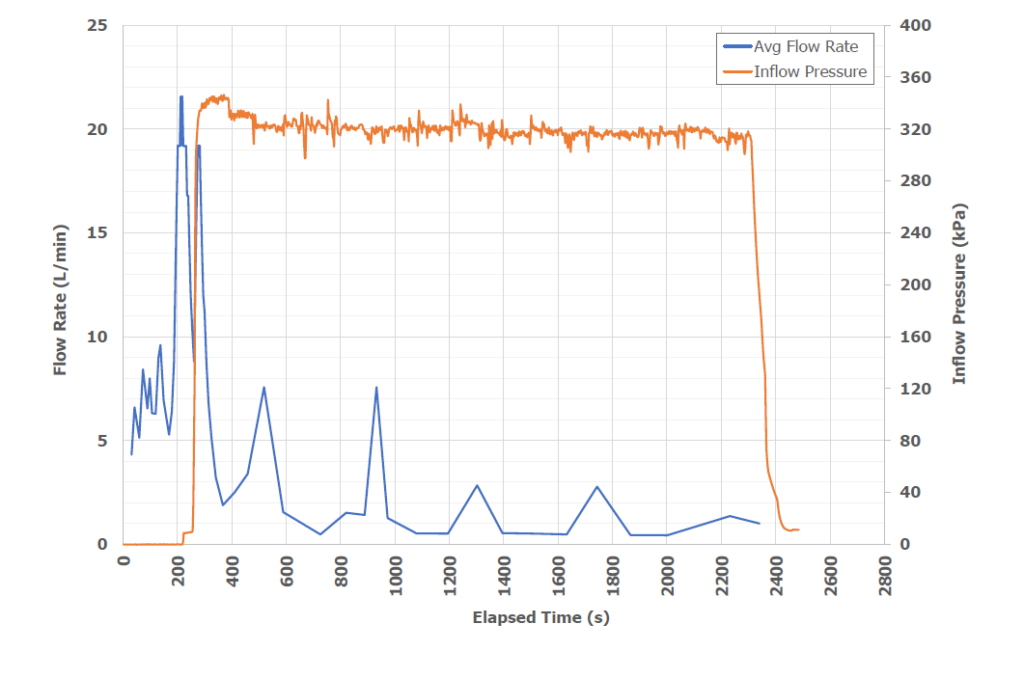

Internal stability testing

Assessment of the internal stability (suffusion) of embankment dam material can be performed to establish the critical gradient where instability occurs. This test can be conducted with either upward or downward seepage flow, and at low or high gradients (0.1 to 20).

Filter compatibility testing/Continuing Erosion Filter (CEF) test

Modern filter design criteria allow for very little erosion of the base material the filter is protecting. Many existing dams either do not have formal filters or have formal filters that do not satisfy modern filter design criteria. This may not prohibit an embankment dam’s ability to filter eroded particles from a concentrated leak if it eventually self-heals after an erosion event.

Our laboratory can conduct Continuing Erosion Filter (CEF) tests to evaluate filter compatibility of a base-filter soil combination and categorize the extent of erosion.

Flume testing

Embankment dam filter material must not be susceptible to internal instability and segregation, and must be able to self-heal a crack under seepage flow. Powertech conducts flume testing on filter materials to determine erosion characteristics and evaluate performance in the presence of a crack.

As part of our current research and development, we have designed a 5-metre long by 1-metre wide fully instrumented testing apparatus. We have also developed and validated test procedures for assessing the filtering performance of a cracked filter. This test will be used to evaluate the response of a granular filter subjected to a concentrated leak.

Other soil testing capabilities:

- Thermal resistivity measurements (field and laboratory)

- Electrical resistivity measurements (field and laboratory)

- Pinhole test for dispersive soils

- Sand Castle test for assessing collapsibility of filters

- Hole Erosion test for erodibility of soils

- Index testing (sieve analysis, hydrometer, Atterberg limits, standard or modified compaction)

For more information contact:

Sasi Sasitharan – 604.590.7412

Engineer Team Lead

NDT Inspections & Civil Technology

sasi.sasitharan@powertechlabs.com

Darren Bromley – 604.590.6616

Director

Generation Technology & Testing

darren.bromley@powertechlabs.com