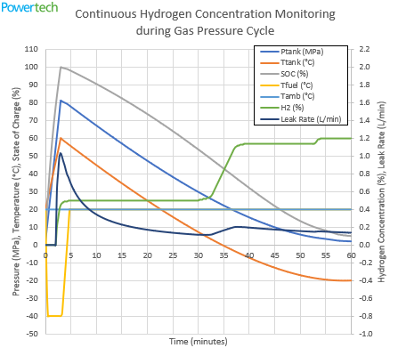

Powertech’s High Pressure Testing department has added continuous hydrogen concentration monitoring to its capabilities. This method allows for measuring gas permeation from a hydrogen cylinder over time, both statically and dynamically (during pressure cycling). Applications include permeation testing and dynamic emission monitoring. The raw data output is in % H2 and is recorded alongside all other sensors such as pressure transducers, thermocouples and flowmeters.

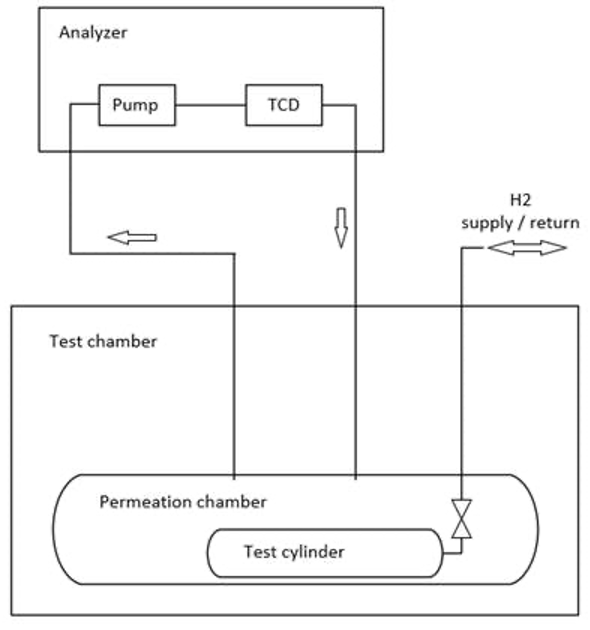

The test is performed in an air-sealed test chamber that contains the test specimen in a nitrogen atmosphere with minimal oxygen. An explosion- proof fan ensures consistent gas concentration throughout the chamber. The analysis loop utilizes a hermetically sealed pump to deliver gas to the Thermal Conductivity Detector (TCD) which then measures the hydrogen concentration.

Before each test, the TCD is zeroed against a reference gas. The test chamber itself is also verified prior to testing by measuring the output of a calibrated leak device with the TCD.

Testing can be performed on tank sizes up to 1800mm in length and 700mm in diameter, with future chamber size upgrades in the planning stages (target maximum tank size is 4500mm in length and 1200mm in diameter). Maximum fill pressure is 87.5MPa during cycling and 95MPa for static permeation testing. For flexibility, test samples can be outfitted with on-tank valves or standard end plugs. Powertech has extensive experience connecting to and operating various makes and models of OTVs.

This service can be utilized with a wide range of fueling methods such as SAE J2601 table-based fueling, MC method fueling and custom ramp rates. These are all possible up to a maximum flow rate of 60g/s, along with defuel flow rate control and monitoring. Furthermore, pre- cooling can be provided down to a temperature of -45°C along with a chamber temperature range of -50°C to 90°C.

For more information, contact:

Tanja Smutny – 604.590.6684

Technical Lead, HITT Engineering

Hydrogen Industry Technology & Testing

Tanja.Smutny@powertechlabs.com